Философия шлифования

oelheld предлагает Вам от бюджетных до высокопро- изводительных масел для шлифования

oelheld предлагает Вам от бюджетных до высокопро- изводительных масел для шлифования

Наши диэлектрические жидкости официально рекомендованы ведущими производителями оборудования

AquaTec моментально повышает производительность и снижает дополнительные расходы

Even though over the last 30 years, spark erosion has been a part of almost every modern manufacturing process, the aviation industry refused this application, due to the nature of the products produced, i.e. highly stressed aero engine parts.

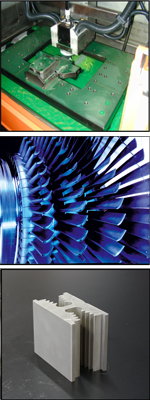

The latest knowledge in the field of spark erosion has changed the approach by aero engine designers, Especially in the manufacturing of the so-called Fir-tree profiles – until today the method of broaching and grinding is used – the procedure of wire cutting is replacing these processes in the field of precision and flexibility of all kinds of geometry.

Even the economical issue should not be underestimated, because on base of the historical costs seven EDM machines can be purchased instead of one broaching machine.

With this in mind, oelheld GmbH became involved among other partners in the European research project called „Advanced Manufacturing Processes for Gas-Engine Turbine Components (ADMAP-GAS)“, by which the processes of wire cutting and water cutting for this production process are shown by comparison.

The fact that the working process of electro erosion wire cutting now occurs in an oil bath, gives you the following benefits:

For many years oelheld has been carrying out research in its own technology center for spark erosion in the field of dielectric fluids for wire cutting. It is this research that has led to the development of cutting fluids that can be utilised in wire spark erosion for the aviation industry.

ADMAP-GAS project details:

Start: 01.08.2009

Duration: 36 months

Budget: € 4,323,946.00

EC support: € 2,883,657.00

Supported by the European Commission by the Seventh Framework Programme.

www.admapgas.com